My Projects

Height-Adjustable System for Agricultural Robot

Context and Challenge

For the company OSIRIS Agriculture, the objective was to design and integrate a height-adjustable suspension system for their crop-irrigating robot. This mechanism had to allow the robot to pass over tall plants without damaging them, while maintaining a compliant road transport profile.

Objectives

- Increase the ground clearance of the robot.

- Ensure road transport within the regulatory width and height limits.

My Role

- State of the art and selection of the most suitable lifting concept.

- Mechanical sizing and validation of the chosen system.

- 3D design and integration into the existing digital mock-up.

- Mechanical strength simulation and analysis using ANSYS Workbench.

Methodology

- Initial discussions with the client to clarify technical and functional requirements.

- Research and benchmark of existing lifting mechanisms.

- Concept evaluation through comparative analysis tables.

- 3D modeling and parametric design using CATIA V6.

- Numerical simulation and stress analysis with ANSYS Workbench.

Technologies & Tools

Mechanical sizing: supplier datasheets, strength of materials calculations.

Software used: CATIA V6, ANSYS Workbench, Excel, Word.

Lessons Learned

Strengthened skills in project management, mechanical sizing, and simulation-based validation.

Rugby Target Project

Context & Goal

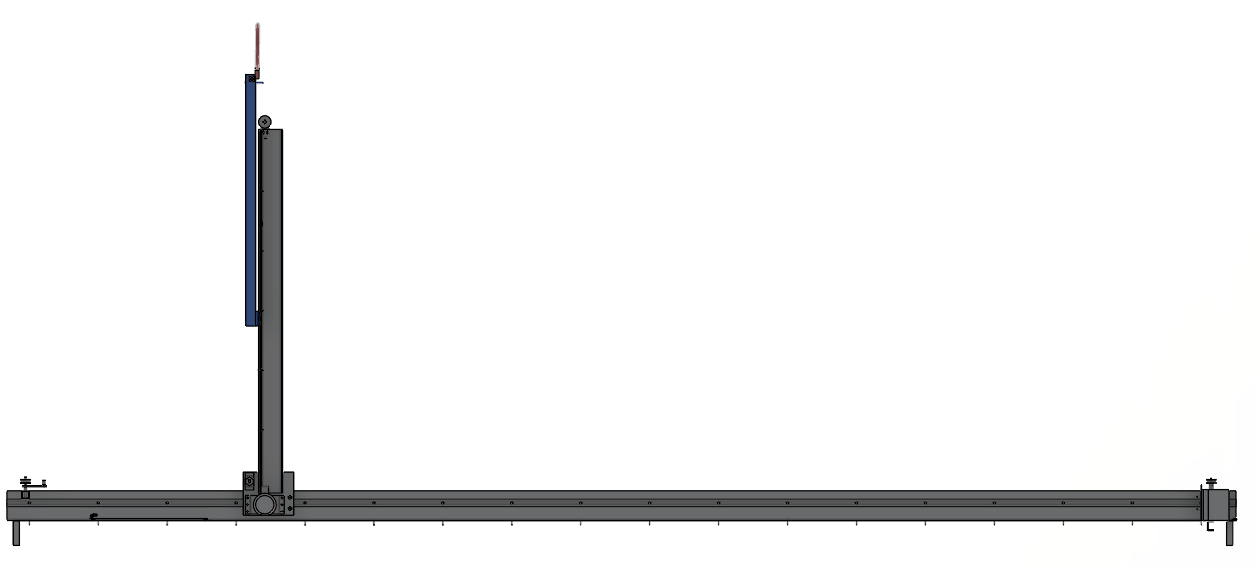

In partnership with Stade Rochelais, the goal was to design a simulation device to optimize lineout training by faithfully replicating players’ movements and dynamics.

Front view

Right view

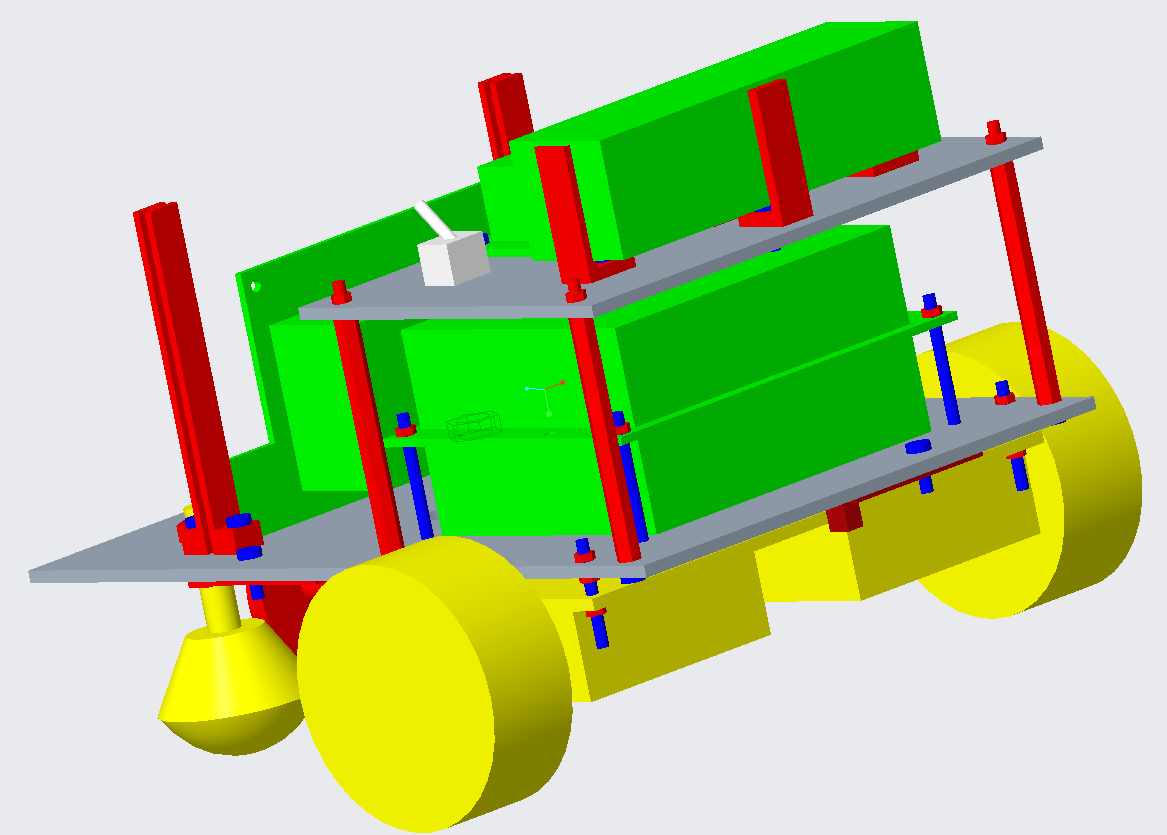

Isometric view

Objectives

- Replicate hookers’ movements during lineouts

- Provide real-time feedback on throw accuracy

- Improve players’ responsiveness

- Diversify players’ strategies

My Role

- Horizontal motion of the target: from design to sizing

- Component selection: rails, rollers, fasteners

- Sizing of rollers, fixing screws, and transmission belt

Methodology

- Client discussions to clarify needs

- Survey of existing solutions and limitations

- Brainstorming, comparative decision table

- Calculations and 3D modeling in CATIA V6

Technologies & Tools

Sizing: Supplier datasheets, strength of materials calculations.

Software: CATIA V6, Excel, Word.

Lessons Learned

Deeper project management, mechanical sizing, and teamwork across disciplines.

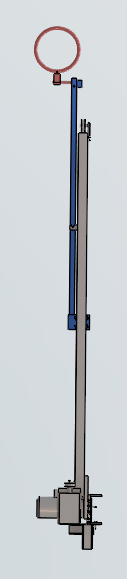

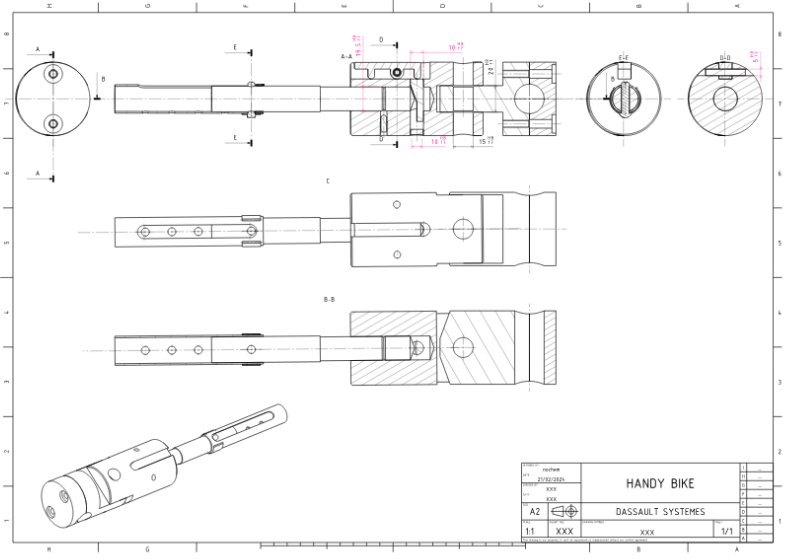

Prosthesis Project for Post-Cubital Amputees

Context & Goal

At the request of an occupational therapist, we designed a forearm prosthesis intended for cycling—adjustable and adaptable to different patients, to facilitate rehabilitation.

Initial functional plans to capture constraints.

3D modeling in CATIA.

Final manufactured prosthesis.

Objectives

- Length-adjustable, multi-patient adaptability

- Secure attachment to the bike and forearm

- Safety in case of fall, easy detachment

- Balance, stability, modularity

My Role

- Design of the bike/forearm link system

- Functional sketches, CATIA modeling, manufacturing drawings

- Geometry optimization, mechanical integration with team

Methodology

- Client exchanges, survey of existing solutions

- Decision matrix, calculations, CAD, drawings

- Fabrication: 3D printing, machining

Technologies & Tools

Software: CATIA V6, Excel, Word.

Machines: Lathe, milling machine, 3D printer.

Sizing: Strength of materials, simulations.

Lessons Learned

Project management, advanced CAD, assisted fabrication, collaborative work.

Ecological and Societal Transition Challenge

Context & Stakes

Team project: making heavy trucks more ecological via electric supply using highway catenaries (pantograph system).

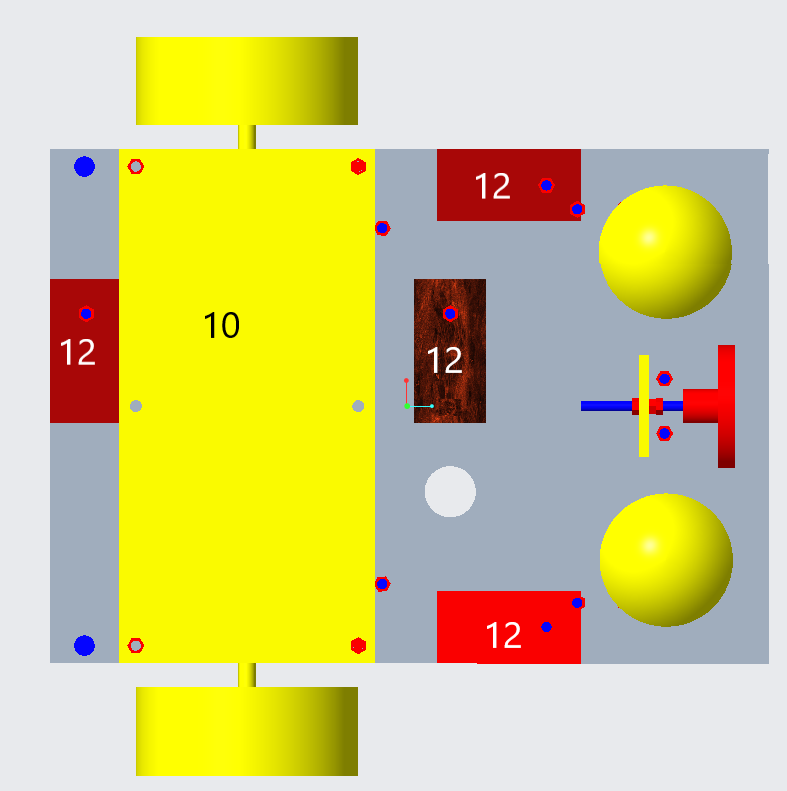

Prototype – top view

Prototype – bottom view

Objectives

- Reduce pollutant emissions of heavy transport

- Design an energy capture prototype

- Assess feasibility and environmental impact

My Role

- Design & fabrication of the laser-cut wooden mock-up

- Re-use of salvaged components

- Presentation & multi-disciplinary restitution

Methodology

- Brainstorming on transport solutions

- Technical & environmental evaluation

- Low-cost physical mock-up

Technologies & Tools

Machines: Laser cutter, multimeter, salvaged components.

Software: Canva, PowerPoint, spreadsheets.

Lessons Learned

First eco-design approach; importance of communication and cross-disciplinary management.

Electric Knife Project

Context & Stakes

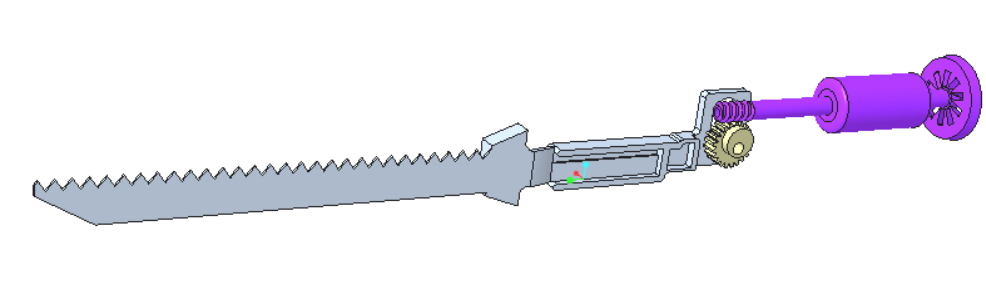

Complete mechanical study and modeling of a domestic electric knife. Kinematic analysis, transformation of motor rotation into blade reciprocation, and 3D visualization.

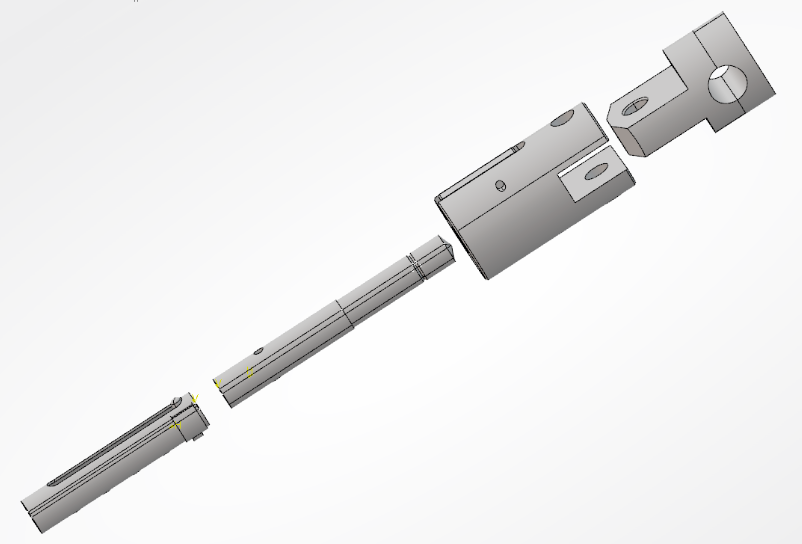

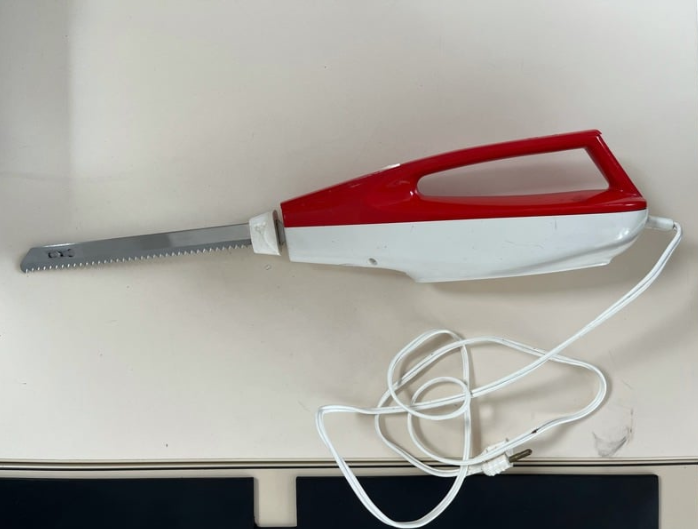

Starting point: disassembly and observation of parts.

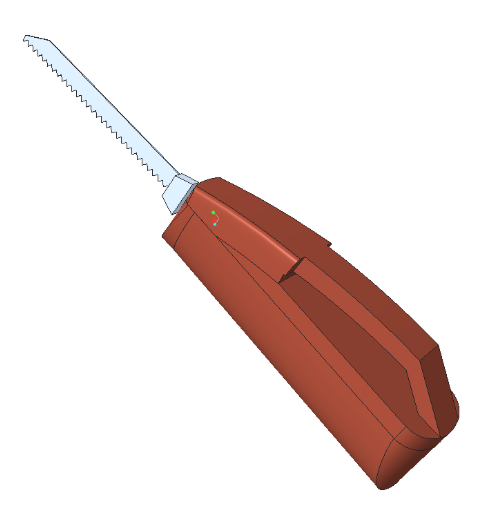

Reconstructed mechanism modeled in Creo Parametric.

Modeled internal mechanical system.

Objectives

- Model parts in Creo Parametric

- Analyze kinematic operation

- Illustrate the system with an animation

My Role

- Kinematic analysis and complete modeling

- Mechanism animation in Creo

Methodology

- Disassembly, component identification

- Link analysis, precise measurements

- 3D modeling, animation, validation

Technologies & Tools

Software: Creo Parametric.

Tools: Caliper, ruler.

Hardware: Real device analyzed.

Lessons Learned

Mastery of 3D modeling, kinematic analysis, animation, and teamwork.

English Project / F1 Board Game

Context & Stakes

Team language project: creation of a Formula 1 board game inspired by Trivial Pursuit (design, rules, physical build, playable in class).

Easy

Medium

Hard

Objectives

- Create an original game

- Improve English through a fun project

- Build a fully playable game

My Role

- Defined the medium and rules

- Wrote and classified questions

Methodology

- Choose the medium

- Rules, questions, printing, 3D pawns

Technologies & Tools

Machines: 3D printer, regular printer, laminator.

Software: 3D printing software, Canva.

Lessons Learned

Teamwork, communication, rigor, creativity, pedagogy.

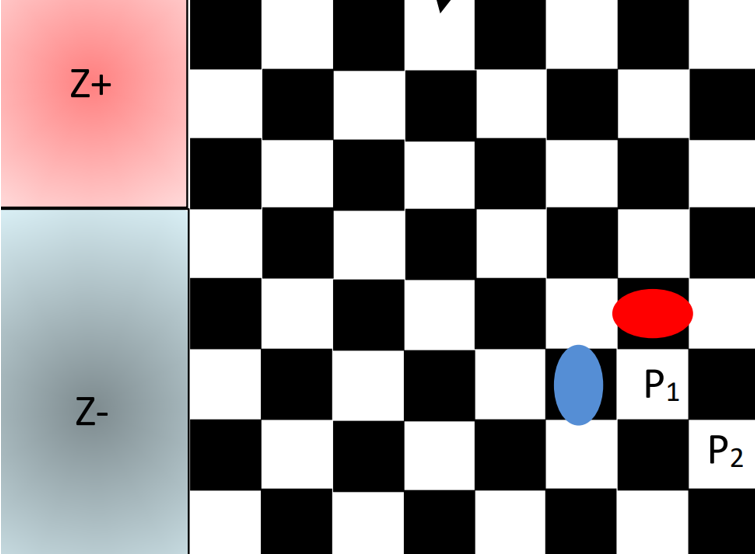

Checkerboard Robot Project

Context & Stakes

Team of 4: autonomous robot moving on a chessboard, grabbing and returning an object while avoiding obstacles. Programming, design, modeling, tests.

Board with mission zones and obstacles.

Rear 3/4 view of the model.

Bottom view with sensor placement.

Objectives

- Develop a reliable hook to tow the object

- Program autonomous path following

- Optimize line/obstacle detection

My Role

- Component choice, assembly, CAD

- Code development & sensor integration

Methodology

- Technical choices, CAD, assembly, tests

- Embedded programming, debugging

Technologies & Tools

Software: Visual Studio Code, component diagram tools.

Hardware: Arduino, sensors, motors, breadboard, etc.

Lessons Learned

Embedded programming, sensor integration, teamwork, rigorous testing.